Paper occupies an exceptional place in people's lives. She had many predecessors. At first, a person wrote on whatever came into his hands: on stones, leaves, pieces of bark, bones, clay tablets. The desired image was scratched onto them using a sharp bone or piece of stone. It was durable but uncomfortable. Therefore, in different parts of the world they began to look for more convenient material for writing.

And this is what they came up with in Ancient Egypt. Along the banks of the Nile, in swampy places, a strange-looking plant called papyrus grew. It was from this that the ancient Egyptians learned to make their writing material. This material was called papyrus. With all my good qualities Papyrus was still fragile, and it was not easy to make. And despite this, it was used for a very long time. Papyrus Tex on papyrus

Along with papyrus, material made from the skins of young animals - calves, goats, sheep, rabbits - became widespread in the ancient world. It was named parchment, after the name of the place where it was invented. In the ancient city of Pergamum in Asia Minor. The method of making parchment was quite complicated. The skins produced a white, thin, extremely durable material - parchment. You could write on it on both sides. Parchment Skin Stretch

Parchment was more expensive than papyrus, but more versatile and durable. In the beginning, scrolls were made from parchment, like papyrus. However, they soon noticed that, unlike papyrus, it can be easily written on both sides. Parchment books became similar to modern ones. The popularity of parchment was facilitated by the fact that on it (unlike papyrus) it is possible to wash off text written with water-soluble ink and apply a new one.

The time of the invention of paper is not precisely established. It is believed that it appeared in China in the 2nd century AD. and gradually penetrated into the West. The raw materials for paper in China were reed, oak and other woody plants. For many centuries, the Chinese kept the secret of making paper. Anyone guilty of revealing the secret was threatened with the death penalty.

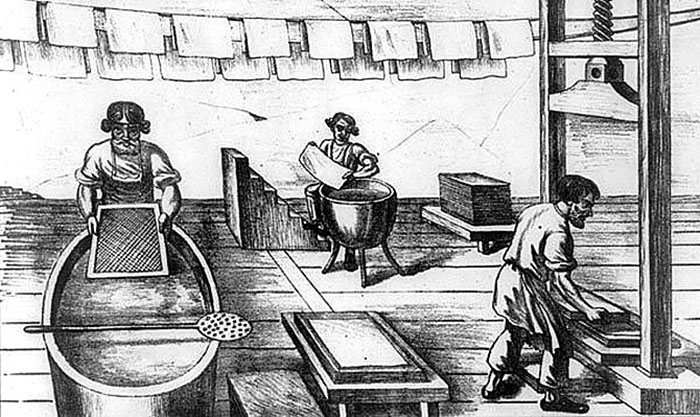

In 751, in a battle near Samarkand between the Arabs and the Chinese, several paper craftsmen were captured by the Arabs. Thanks to this, the East learned the secret of paper. From the Arabs the secret spread among the European peoples. Around the 10th century, the presence of paper mills could be observed in many European countries. The process of making paper requires a large amount of water, so paper mills sought to be built as close to the water as possible, and more often - right on the river. Such places became known as “paper mills.”

Gradually, paper production improved. The merit of the Italians is especially great for this. On the territory of Russia, paper appeared only in the middle of the 16th century. It was then that Batu Khan, who had captured Russian lands at that time, conducted a population census and introduced the Russian people to the “Chinese miracle” of paper. And the rise of the Russian paper business occurred during the reign of Peter the Great. And it was then, or rather, in 1703, that the world’s first Russian newspaper was published.

Paper production is being improved thanks to the invention of various machines that produce paper. The most significant was the machine, which made it possible to make very thin and long sheets. It was invented in 1798 in France. And at the end of the 19th century, the paper machine reached its perfection and became fully automatic.

Already by the 20th century, paper production was a large-scale and mechanized production with a variety of products. Today, this production has been further improved and has an even greater variety of products. And absolutely everyone on the planet can use this product.

Paper is a material for writing, printing, drawing, packaging, hygiene needs, etc. Paper is usually made in the form of sheets or rolls. The raw material is cellulose, which in turn is obtained from plant material or recyclable materials (rags, waste paper).

Download:

Preview:

https://accounts.google.com

Slide captions:

The logs are brought to the factory.

Paper is made from cellulose.

Preview:

To use presentation previews, create a Google account and log in to it: https://accounts.google.com

Slide captions:

How to make Radzin paper R.G 344z2

The first writing sheets were made from papyrus. Papyros is a giant perennial herbaceous plant up to 5 m high and its stems up to 7 cm in diameter.

Then they began to use it to make paper. special kind nettle – hemp nettle

A search was underway for new material. And he was found. Wood began to be used as a raw material.

Paper is produced at a pulp and paper mill.

The logs are brought to the factory.

Chips are obtained from logs - small chips. It is boiled in a special solution.

Cellulose is then obtained from the wood chips.

Paper is made from cellulose.

They roll up huge rolls of paper.

Large sheets of paper are cut into small sheets on machines.

But how does a huge tree make a beautiful notebook, book or stack of white sheets? Let's figure this out together.

How paper is made

Paper is produced in paper mills. Logs are brought from the forest to the factory. The most commonly used are pine, spruce, birch, as well as eucalyptus, poplar, and chestnut.

On a special platform, the bark is stripped from the logs and crushed into chips. The fragments are then transported on a conveyor belt to a pulp mill, where they are boiled in a special solution. The result is cellulose, the main raw material for paper production.

Interesting! One tree produces 2857 notebooks of 12 pages. It takes 60 years to grow a mature tree. That is why it is important to use textbooks and notebooks carefully, because all of these are cut down trees.

The most economical way to obtain wood pulp is mechanical. The wood processing plant grinds the timber into crumbs and mixes it with water. This is how low-quality paper is made - for example, for newspapers.

But for the production of high-quality paper - for magazines, books and brochures - they use chemical method. Using sieves, the fragments are sorted by size. Next, the crushed wood with the addition of acid is boiled in special machines.

The cellulose then passes through filters and is washed to remove impurities. At this stage, waste paper can be added to the raw material, but it must first be cleared of ink.

The next step is adding adhesives and resins. The first ones repel moisture, the second ones prevent the spreading of ink, which is often water-based. It is thanks to these processes that what is written in your notebook does not smudge and is easy to read. Printing paper does not require such sizing, because printing inks are not water-based.

But that's not all. Then pigments and dyes are added to the paper raw material. For example, white paper is obtained by adding kaolin.

After this, the paper pulp enters the paper machine onto a conveyor belt. Here, with the help of tiny porous holes and pressing with various rollers, moisture is removed from the paper and a continuous roll of tape is formed.

At the “wet pressing” stage, the paper is finally dried, dehydrated and compacted. The result is a smooth white tape wound onto a huge roll. The paper is ready! Can be sent to book factories. There, the paper web is cut to create books and notebooks.

You can learn all the intricacies of paper production from the video.

How are books made?

So, after the author writes the text and the editor of the publishing house approves it, the proofreading process. The work is checked for errors. Ideally, the proofreading team reads the text several times. After this, illustrations are selected for the book.

Then it begins layout. Using a special computer program, the layout designer selects the book format, margin size, types and sizes of fonts, and determines the location of illustrations and text.

The next stage is called color separation. Did you know that to print a fashion magazine cover you only need four colors: blue, pink, yellow and black? Therefore, now the designer must divide all illustrations into four components.

The most important stage is book printing. Using rollers on a printing machine, the ink is rolled out to a thin layer, fed onto a printing plate, which rotates and applies the image to a continuous roll of paper.

Interesting! Printing house workers can print several thousand sheets in one shift.

It is difficult to imagine any book without a cover. Therefore, the next stage is creating the “face” of the future book. If the cover is ready, it is placed on the book block and trimmed. If a hard cover is being made, the book is trimmed before the cover is glued on.

That's all - the book is ready to delight the eyes of admiring buyers, all that remains is to pack it. You can see with your own eyes how books are made in the next video.

What were books and paper made of in ancient times?

Once upon a time there were no books in the form in which you see them on store windows or in libraries today. And all because people did not know how to make them. Instead of paper, humanity used cave walls, stones, dishes, tree bark…

Years passed and people came up with the idea of making records on wet clay. However, such books were too heavy, inconvenient and short-lived.

After some time, the heavy clay cloth was replaced calf or goat books skins are light and practical. Since the first such book was created in the ancient city of Pergamum, the “paper” made from animal skin was called parchment.

However, such material was too expensive, because to create one book, it was necessary to slaughter many calves. So people kept looking for cheaper and easier ways to create books. And they succeeded.

Along the rivers of Africa there grows a tall marsh plant - papyrus. People did not immediately realize its amazing properties. At first, the plant was used in the construction of houses. But one day a man was repairing his house. I cut the stem, took out the fibrous center and put it in the sun. Imagine the man’s surprise when he noticed that the fibers had turned into dry, narrow ribbons. And when he saw that papyrus also absorbs paint well, he realized: you can write on papyrus! This is how books made from papyrus appeared.

But who and when invented paper as we see it now? Researchers assure: the palm belongs to the Chinese. They came up with the idea of producing paper from young bamboo shoots.

Interesting! ...And before that time, the Chinese wrote on silk or bamboo tablets. The Chinese jealously guarded the mystery of silk production. However, silk was very expensive, which means-inaccessible to the majority of the population, and bamboo- too heavy. Only 30 hieroglyphs were placed on one board. Information has been preserved: in order to transport some works, the Chinese needed a whole cart.

Chinese chronicles report that invented paper in 105 AD. e. Tsai Lun.

“Everyone highly appreciates the work of Tsai Lung: he invented paper, and his glory lives on to this day...”- says the chronicle.

The 4th century was a turning point in the history of paper making. After the technology of its production was improved, paper replaced bamboo planks forever. New experiments have proven that paper can be produced from cheap plant materials: tree bark, reed, bamboo. The Chinese were especially happy about the latter: bamboo is a dime a dozen in their country.

No matter how hard the Chinese tried to keep the secret of paper production, they failed. In 751, during the fight against the Arabs, several Chinese craftsmen were captured. From them Arabs They learned the secret of creating a mysterious product and for five centuries they profitably sold it to Europe.

Oddly enough, but Europeans were the last of the civilized peoples to learn how to make paper - somewhere in the 11th-12th centuries. The Spaniards were the first to borrow paper production technology, then the Italians, Germans, English... It is interesting that for a long time paper was made not only from soaked tree fibers, but also from rags and other rags.

The first industrial paper production machine was invented in France in 1798.

On the territoryand Ukrainian lands Paper production began in the 13th century in Galich. However, documented information about Ukrainian paper “factories” has been preserved since the 16th century. Researchers of the history of the Ukrainian paper industry have found materials about 200 “factories” that operated on the territory of Ukraine from the 16th to the beginning of the 20th century, which indicates the high cultural level of the then population.

Radomysl Castle in Radomysl, ZhitomirShchyna is the first paper mill in Central Ukraine, built in 1612.

Now paper surrounds us everywhere, conquering more and more new areas of application every year. That is why it is so important to remember that it is made from trees - forest resources that are catastrophically decreasing every year on the planet.

Treat books with care, use paper sparingly, recycle waste paper, plant trees - the least that everyone can do to preserve forests. And one inventive boy, in order to preserve forest plantations, even refused to write an essay. =)

Back Forward

Back Forward

Attention! Slide previews are for informational purposes only and may not represent all the features of the presentation. If you are interested in this work, please download the full version.

Purpose of the lesson:

- Introduce children to the history of paper;

- Draw the attention of preschoolers to the importance and variety of paper in our lives;

- tell about its purpose and manufacture;

- develop research activities, cultivate interest in understanding the world around us;

- Develop memory, attention, thinking, speech;

- Draw attention to the need for careful use of paper, to the connection between forest protection and our everyday life.

Material for the lesson: Samples of paper for examination, napkins, water, PVA glue, starch, non-woven napkins (towels), modeling boards, peas (or any other material as a press)

Progress of the lesson

The teacher comes in and brings in Pinocchio holding an envelope with a letter in his hands.

Educator: Guys, today we have a guest, say hello to him. (The children say hello, Pinocchio answers them).

Educator: But Pinocchio came to us for help. He received a letter from school, in which there were pieces of different paper and only one question written: “What is this for?” Let's look at these pieces and try to help Pinocchio.

Children look at the papers and express their guesses.

Educator: What do you think, if a person had not invented paper, what could replace it? (Children's assumptions.)

Educator: Well done, they came up with a good idea. Indeed, (we start watching the presentation)

Slide 2: Man invented writing material long before paper appeared.

At first they wrote on damp clay tablets. Our distant ancestors dried them in the sun or burned them in fire to fix the text. After this, the tablets could be sent to each other, including over very long distances. But these tile letters were very inconvenient (heavy and fragile), and their production took a lot of time.

Slides 3 and 4: B Ancient Greece and in Rome people wrote on wooden tablets covered with wax. This was already significant progress, since the layer of wax made it possible to erase the old text and write a new text on the same tablet. In Rus', such wax-coated tablets were called cerami.

Slide 5: But our Slavic ancestors wrote their texts on birch bark, that is, on the outer layer of birch bark. Their ancient letters are called birch bark letters.

Slide 6: The ancient Egyptians, about 4,000 years ago, took stems of papyrus (a local plant), peeled off the skin and straightened it. Then the strips of papyrus were laid crosswise and pressed so that they stuck together. A dried papyrus sheet was good material for writing.

Slide 7: The book of that time was a papyrus scroll. When reading, the papyrus ribbon was gradually rolled from one side to the other so that two columns were simultaneously in the field of view, and the rest of the scroll was rolled up

Slide 8: In the 2nd century BC in Asia Minor in the city of Pergamum, writing material was made, but not from papyrus, but from the skins of young animals processed in a special way - calves, lambs, goats, donkeys. After the name of the city, this material became known as parchment. Unlike papyrus, parchment was much stronger, more elastic, more durable, it was easier to write on it, on both sides, and if necessary, the text could be easily washed off and a new one applied. But despite these advantages, parchment was labor-intensive to make and was an expensive material.

Slides 9 and 10: Before the invention of paper, people in China wrote either on bamboo tablets or on silk. But silk was always very expensive, and bamboo was very bulky and heavy. An average of 30 hieroglyphs were placed on one tablet. It’s easy to imagine how much space such a bamboo “book” must have taken up. It is no coincidence that they write that a whole cart was required to transport some works.

Slide 11: But paper itself was invented in China by Tsai Lun. He found a way to make paper from the fibrous inner bark of the mulberry tree.

Slide 12: Traders from China traveled far to the north and west, and came to the city of Samarkand. There the Arabs adopted the secret of paper making and brought it to Spain. From there, the art of paper making spread throughout the world.

Slide 13: Over time, all sorts of methods were discovered and created different cars for paper release. One of the most important was a machine that made it possible to make long and very thin sheets of paper. It was invented in France in 1798.

Slide 14: Currently, paper is made from shredded wood. First, trees are cut down in the forest. The logs are taken to the factory. Here they are cleared of bark and ground into small pieces - crushed in a machine (crusher). The resulting crumb is mixed with a special liquid, turning it into a soft mass. It goes to making paper. But the tree takes a long time to grow, and people need a lot of paper. In addition, trees and other plants are needed to purify the air we breathe. People are trying to save forests, so they came up with machines that make new paper from used paper (waste paper).

Do you want to try making paper yourself? (Children’s answers, let’s go make paper, the material is taken from the book “Scientific Experiments”).

Pinocchio (after the paper was laid out to dry): Thank you, guys. I learned a lot of new things today, but I haven’t learned all the new names yet. Let's repeat it again... (Pinocchio asks questions about the material he viewed, the children answer, the teacher helps if necessary.) Then Pinocchio says goodbye and asks permission to come again.

Making paper yourself

1. As a base, take 2-3 napkins, chop them (you can tear them into small pieces with your hands or cut with scissors, the smaller the better)

2. Fill these scraps with water, preferably warm.

3. Add a teaspoon of PVA glue and a tablespoon of starch to our mixture so that the sheet is elastic and can bend.

4. Stir this mixture, it turns out to be a liquid porridge.

5. We spread our porridge on the mesh from under the children's mosaic (lay it out in a thin, even layer). To do this, it is best to pour water into the container on which the screen is placed (tray, baking sheet, etc.) so that it covers the mesh with the mass. We level the porridge and then drain all the water.

6. After this, blot our “sheet” of paper with a towel until it becomes almost dry.

7. It's time for final drying. We leave the sheet under the press (peas) so that it does not warp.

8. After final drying, we got a very beautiful paper self made.

To use presentation previews, create a Google account and log in to it: https://accounts.google.com

Slide captions:

History of paper

ROCK PAINTINGS

CLAY TABLETS They were inconvenient to carry and store, they were heavy, fragile, and easily broken.

EGYPTIAN PAPYRUS

PARCHMENT FROM LEATHER Parchment was very heavy and expensive. It took a herd of calves to make one book.

The Chinese kept the secret of making paper secret for many centuries. After 800 years, paper was made all over the world. Wood is used as a raw material.

Paper is produced in pulp and paper mills

First you need to prepare wood, cut down a lot of trees.

LOGS ARE BROUGHT TO THE PLANT

Chips are obtained from logs - small chips, then they are COOLED IN A SPECIAL SOLUTION

The result is a slurry, which is squeezed out and fed to a paper-making machine. The pulp is distributed, dried, ironed.

The finished paper is wound onto huge rollers.

Huge rolls of paper are being wound up.

Then it is cut into sheets and folded into bundles. The paper is READY!!!

The lumberjacks cut down the tree, divided it into parts on a machine, chopped the logs into chips, and boiled them in a solution for a long time. And then all the liquid is squeezed out, ironed with a roller, dried, ironed. So it turns out blank slate paper For magazine, book and notebook.

In our lives, paper is found everywhere and is used everywhere.

WHAT'S EXTRA HERE?

Trees are an important part of nature. They decorate our planet!

The forest is home to many animals and birds.

Trees clean our air!

We must use paper sparingly to save trees. Used paper (called waste paper) can be made into paper again. This way we will save the lives of many trees in our forests.

On the topic: methodological developments, presentations and notes

Notes on the surrounding world in the senior group "History of the emergence of Moscow."

To consolidate children's knowledge about the history of the origin hometown. Introduce you to the founder of your hometown....