Hello dear readers! I continue the series of articles about the new kitchen, and here is the second part, which will tell you about the very first practical step in this matter. The first part was devoted to

In fact, a kitchen set is a set of furniture that has its own dimensions. An important difference between kitchen furniture and furniture for living rooms is that it is equipped with a large number of technically complex mechanisms and fittings, and the intensity of use of this furniture is several times higher than that of ordinary room furniture.

As a rule, the price of 1 linear meter of "kitchen" is much higher than the price of 1 linear meter of any other furniture, of course, if the manufacturer, quality and materials are the same.

From the foregoing, the conclusion suggests itself that the order of a kitchen set must be approached with special care, which we will do, starting with measuring the room!

How to take measurements of the kitchen.

Making your own is pretty easy. You will need a tape measure, pencil and paper. If you have a laser tape measure, it's even better, but then you probably already know how to measure rooms 🙂

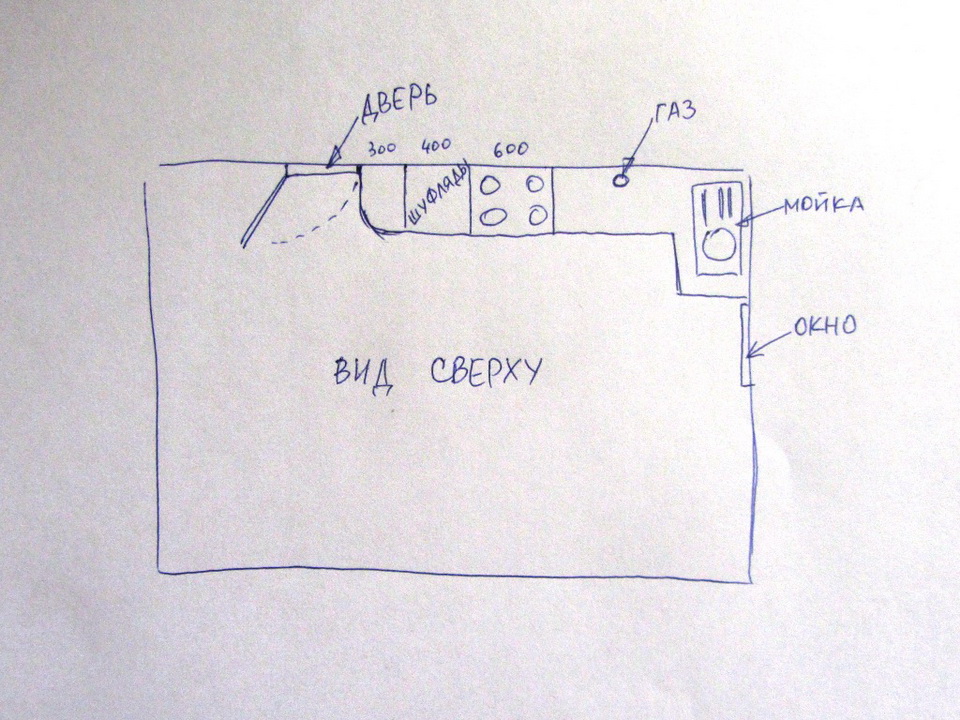

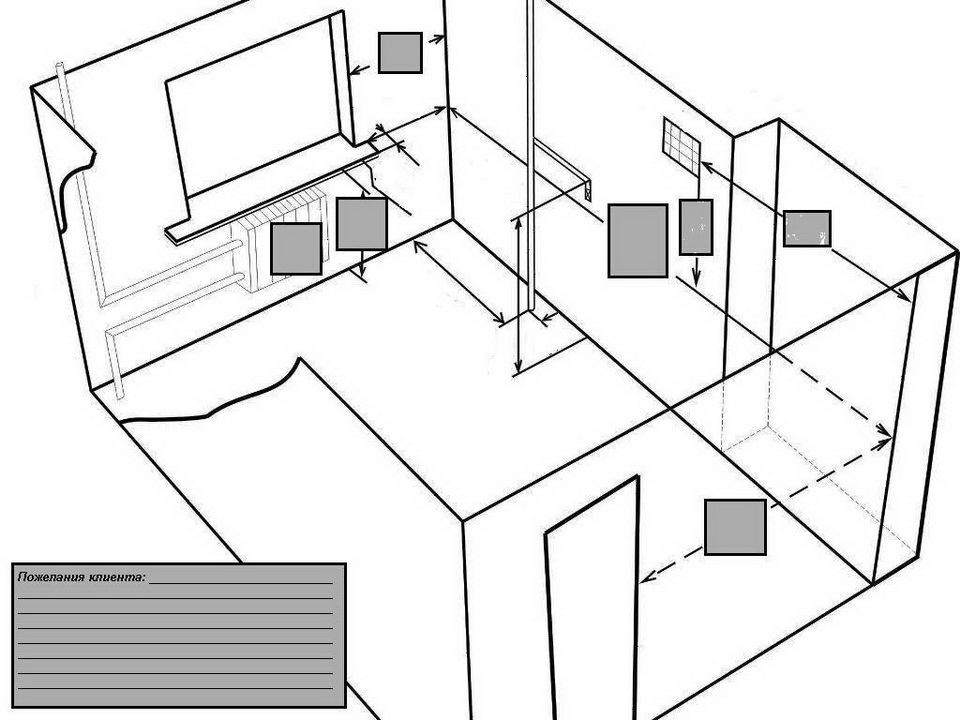

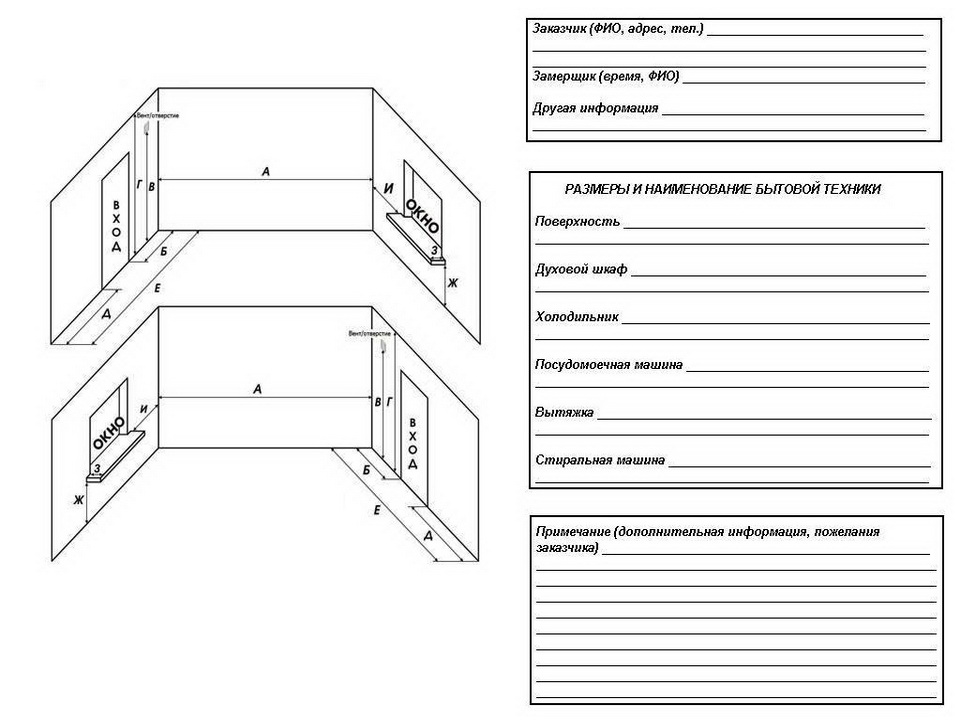

The plan that you see below (the picture can be enlarged, it will open in a new window) shows a standardized kitchen room. It reflects all the main places that need to be measured.

The main focus is on wall C2, along which the kitchen will stand. Please note: if you have adjacent walls (C1 and C3), be sure to repeat measurements C, D and D on them at a distance of 600 mm from wall C2. Thus, you will recognize the curvature of the walls at the installation site of the future kitchen. You should always focus on the smaller number of all six. If V, D, D \u003d 3000 mm, and at a distance of 600 mm from C2, for example, D \u003d 2700 mm, then your actual length for arranging furniture is 2.7 m. Additionally, record the lengths of walls C1 and C3.

I also prepared a short video for you, which clearly shows important points when measuring a room. It is, as always, at the end of the article.

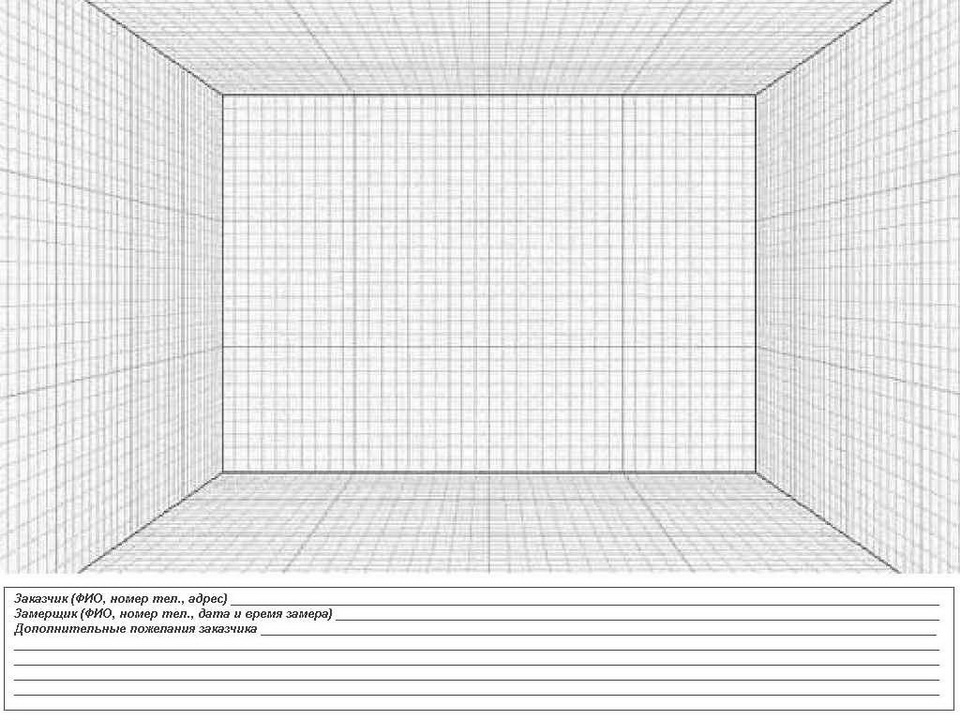

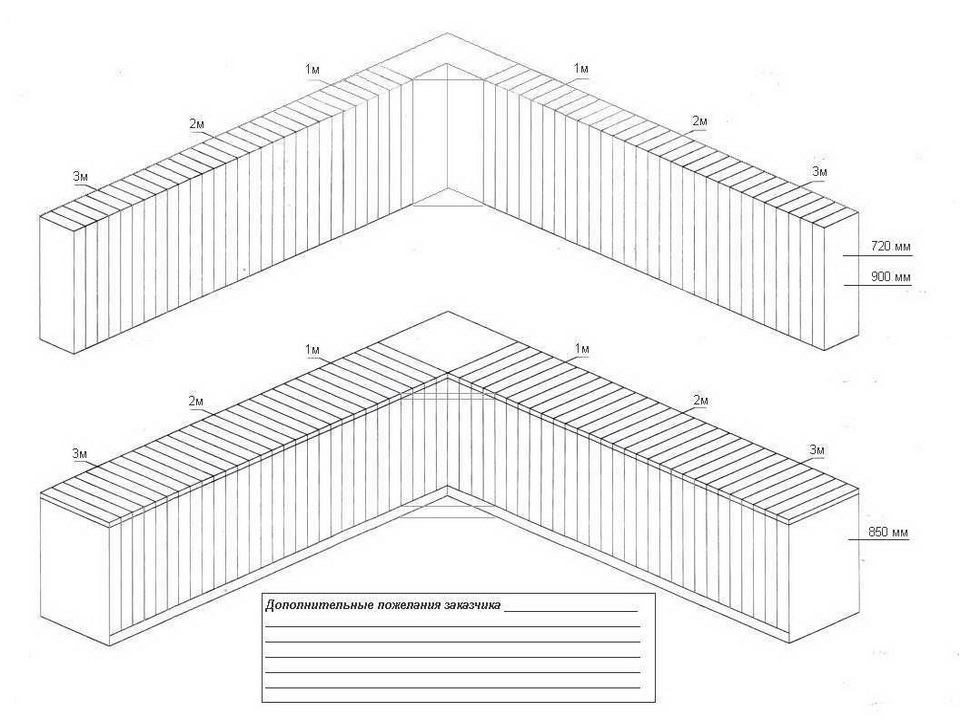

Are you planning to visit the kitchen showroom to ask the price and look at the kitchen, as they say, "live"? You can download the kitchen measurement form in high quality. Print it out, put your measurements on it and take it with you to the salon.

Perhaps your room has a different configuration or it does not have, say, a gas pipe - this means that you simply will not need to measure these objects. The meaning is always the same.

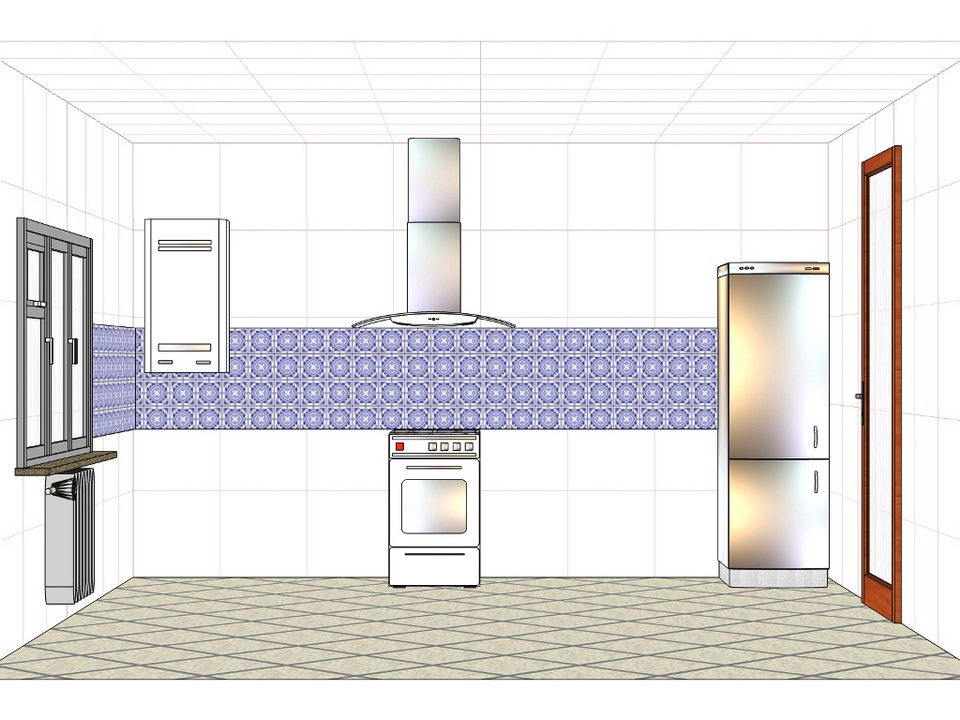

For greater clarity, I will give an example of a kitchen set that can be placed in the room shown on the template.

Do the measurement yourself or call the measurer from the salon?

Most KCs (kitchen salons) measure your kitchen themselves and for free. Surely you, studying their sites, have already paid attention to this. You can call the measurer home by simply calling on the phone. It is very convenient and correct. But I always recommend measuring the kitchen 2 times: the first one on your own, the second let the measurer do. Why is it needed and what does it give:

- Self measurement . This is an initial measurement, it can be carried out at any time convenient for you. Gives you an idea of the possibilities of the room, its size, hidden defects that may interfere in the future.

- official measurement . This measurement is carried out by a specialist of the company in which you will order the kitchen. Based on these data, the factory will produce furniture for you. It also gives all the necessary data about your premises. It is more complete and of high quality, as it is carried out by a specialist.

Not every person will be able to immediately answer the question of what parameters his kitchen has: the length, width and height of the walls, the area of \u200b\u200bthe room, and many others. Knowing the answers to these questions, even in in general terms, you will be able to determine which "kitchen" is right for you, and which set just won't fit in your kitchen. In the process of measuring, you will visually examine your kitchen for technical nuances: pipes, corners or ventilation ducts.

I perfectly understand that you already know where and what pipes you have, but most likely at the level of “we have a gas pipe and this is a problem”. In fact, it may turn out that there is no problem in this pipe, but for this you need to explore the room.

The conclusion is: do the initial measurement yourself - this will greatly simplify and facilitate your choice of a new kitchen, its planning. It will show you the problem areas, over the elimination of which you need to think. Save your time.

Do not be lazy, take measurements yourself and you can immediately start designing your future kitchen.

Calling a measurer from the salon

Today, almost all CS have this service, and for many it is also free. I will say right away - this is a very important procedure, and it must be done! I'll explain why. The fact is that the measurement made by the factory is an official document. Based on it, the consultant will calculate your kitchen. If, after manufacturing, it turns out that the kitchen, for example, is 3 centimeters larger than necessary, then this is the fault of the factory and it pays, BUT, if the consultant calculated the kitchen according to your size, it is your fault and you pay. A simple formality, but what are the differences 🙂

By the way, if you measured the premises yourself, then it will be easier for you to communicate with the measurer from the factory - you will already be “in the know”, and you can immediately draw his attention to problematic or difficult areas, if any.

As a rule (for serious companies) their letterheads for measuring the premises. The measurer himself should have a laser tape measure, and not climb around the kitchen with a simple metal one. If the measurer works with a cheap and simple tool, draws up a measurement somehow, and even on a simple piece of paper - this is not a very good sign.

Information that must be on the measurement sheet:

- Full name of the measurer, his signature and company name.

- Measurement address and date.

- Full name of the customer, his signature.

- Contact numbers (yours and measurer)

- If required, appropriate notes should be written. For example: “To calculate the cuts, see photo” or “The floor level will rise by +3 cm before installation begins” and so on. All notes must be accompanied by your signature and the measurer's signature.

On this, almost all the main things about measuring the kitchen, I told you. Of course, there are still many nuances and aspects. Can water pipes be moved? How to close pipes in a wall? Ventilation and much more, but I will talk about this in the next article.

Dear readers, if you saw an error, or I missed something when talking about measurements, share your experience in the comments - it will be useful to all of us.

The long service life of the window structure depends not only on the quality of the product and installation, but also on the correct measurement. It is during the measurement that the technical plan of the future product is formed, based on the specific conditions of the glazing object. The consequences of a competent measurement are the manufacture and installation of products in accordance with GOST and saving the customer's money.

Stages of measuring a window opening

1. Product specification- plastic, aluminum, and even more so wooden windows have their own characteristics, for example: the width of the box, the presence of a support profile and even the weight of the product can make adjustments to the measurement. Therefore, before taking measurements, it is necessary to agree with the customer on the profile of the future window.

2.

General window horizon- if the openings for the windows are located close to each other, which is often found in suburban construction, it is necessary to check the compliance of the openings with the same level and, if necessary, amend the measurement.

If this point is not taken into account, during the installation process it may turn out that the windows and, accordingly, the window sills will be located at different levels relative to each other. The discrepancy between the level of window sills is a consequence of incompetent measurement and may lead to a claim against the measurer or the window company.

The general horizon for windows is easy to determine with a laser level or a building rule.

3. window opening measurements- the length and height of the opening are measured (from wall to wall). For openings where windows are not installed, this is not difficult to do. But in those cases when the windows are already in place and the pigtail is made, it can be quite difficult to take the correct dimensions, since it is impossible to determine where the window / door frame ends and the building wall begins. To eliminate errors, the dimensions of the opening are taken from two sides: from the side of the room and the street. By comparing these dimensions, the dimensions of the new window are calculated.

At this stage, the following rules should be taken into account:

The distance between the wall and the translucent structure (“mounting seam”) should be within 1.5-5 cm (the average value is taken from GOST 30971). But for high-quality filling of the seam with mounting foam, the range of joint sizes recommended by manufacturers is: 1.5-3 cm. If the distance is less than 1.5 cm, there is a risk that the mounting foam is not extruded in the right way, which can lead to cold bridges and the occurrence of condensation and fungus around the perimeter of the window. Also, such a small size can complicate the installation of window slopes. Otherwise, with a gap of more than 3 cm, there is also a risk of incomplete extrusion of the foam, therefore, in this embodiment, the mounting foam is applied in 2-3 steps with a time delay of 10-20 minutes. With significant gaps of more than 6 cm, in order to avoid overspending of the mounting foam, it is allowed to use heat-insulating materials - expanded polystyrene or mineral wool.

Whatever the dimensions taken inside the room, it is also necessary to make sure that they correspond to the opening from the street side, namely, to make sure that the predicted edge of the window frame goes into a quarter of no more than 3 cm (in openings with a quarter), and also to make sure that there are no obstruction for the installation of drainage.

4.

Drainage measurement- in modern windows, a support profile is provided for fixing the drainage system and the window sill. The “stand” is attached to the lower profile of the frame, its height is 3 cm. It is important to take this nuance into account and calculate the height of the new window, taking into account the stand profile in such a way as to ensure that the drainage is fixed at an angle of 110 degrees or more.

The length of the drainage corresponds to the width of the opening, and in cases of installation of ebb tides with flanging, 5 cm is added to the length. The width of the ebb is measured so that the ebb drip recedes from the wall by 4-7 cm. the appearance of noise in windy weather or noise from falling drops on rainy days.

When measuring the dimensions of the drainage, it will not be out of place to pay attention to and include in the estimate the material for the exterior finish of the slope, this can be plaster, expanding PSUL tape, plastic-metal trim, etc. The material for the street slope is selected taking into account the specific features of the building and is agreed with the customer.

5. Measurement of window sills and slopes. There are no strict standards for installing window sills, so the measurer is required to clarify with the customer the desired parameters: the width and extension of the window sill beyond the plane of the wall and, based on these wishes, make measurements. If repair work is carried out on the wall where the window is located, then the value of the finishing material of the slope should be increased by the required size.

Attention: an excessively large window sill outlet prevents natural air circulation from the central heating battery. This negatively affects the heating of the room and may contribute to the formation of condensation on the glass. The recommended battery overlap size is ⅓. In cases where the window sill significantly overlaps the heating element, ventilation holes are made in the window sill to allow warm air to pass to the window plane.

Important: warn the customer that when dismantling old windows, there is a high probability of damage to the perimeter of the opening on the wall adjacent to the window; it can be chipped plaster or damage to the wallpaper.

6.

Additional Information.

In addition to fixing the dimensions, the order estimate indicates such data as:

- Manufacturer, interior and exterior color, window profile;

- Option to fill the frame glass, double-glazed window (formula), sandwich panel;

- Hardware manufacturer, type of opening;

- Availability and number of mosquito nets, handles with child protection;

- The floor of the building where the work will be carried out;

- Option for lifting products: manual, on an elevator, on slings;

- If necessary, a mark on the removal or removal of garbage is made on the measurement form;

- The points that do not affect the cost of the order are specified: the allowable working time of the installation team, the availability of electricity in the work area, a place for storing products, etc.;

- Contact details of the customer;

7. Customer consultation. The responsibilities of the Measuring Officer include:

- Consultation of the customer about the features of window systems and materials (technical specifications, warranty periods);

- Precautionary advice on possible noise during work and pollution of the premises, etc.

- Notification of the customer about the need to install a "Children's lock". (GOST 23166-99 in part of clause 5.1.8, which were put into effect on 09/01/2016 by the order of Rosstandart dated 02/17/2016 number 168 art.).

Documentation

The documentation contains the current GOSTs for the installation of window structures, as well as pvc window measurement form.

Conclusion: as you can understand from the article, measuring a plastic window is an extremely important procedure that requires certain knowledge and professional skills. Therefore, if you have doubts about the correctness of your sizes, order this service from professionals. The Fenster SPb company has the necessary specialists who will not only measure the opening for a plastic window, help in choosing a window profile, but also calculate the cost of the order right on the site. More about the service.

Why do you need preliminary measurements of the kitchen? Why is it better to trust a professional measurer? How to distinguish the competence of the master and the furniture company as a whole, even at the stage of measuring the premises? What is fraught with the wrong measurement of the room?

These and other questions are answered by the chief technologist of furniture production Timur Denisov.

What measurements can be considered correct

Correct or accurate room measurements- this is a professional measurement of the room, taking into account the nuances present: the presence of sockets, batteries, communications, a boiler-column, windows, doorways and other things.

When measuring a room, it is necessary to take into account the curvature of the walls, floor and ceiling. It is also recommended to measure the distance to all objects from several points, relative to parallel and perpendicular planes.

Buying Ready furniture set, consisting of several sections (kitchen, nursery, bedroom, living room, etc.), it is very important that the installation of furniture goes quickly and smoothly. And even more so, correct measurements are simply necessary for calculating custom-made furniture.

Typical problems that arise when measuring the kitchen incorrectly:

- Sockets are located below the countertop or rest against it;

- Pipes of various communications fall on the sidewall of kitchen furniture;

- It is impossible to use a valve that shuts off the supply of water, gas;

- Built-in appliances rest against sockets, pipes or ledges in the wall;

- Independent appliances above/below the standard kitchen drawer size;

- Furniture blocks the window or doorway, thereby preventing the full opening of the door, window;

- There is no free access to communications, sockets;

- Furniture facades do not open, rest against the ceiling, beat the handle against the walls, touch the lighting fixtures;

- The hood is located far from the vent;

- The sink and dishwasher are further away than the instructions require;

- Lack of length of "native" hoses and wires from household appliances to connection to the necessary communications;

- Due to the curvature of the walls, gaps are formed during the installation of countertops and much more.

How to make the correct measurement of the room

It is a mistake to believe that anyone with a level and a construction tape measure is able to correctly measure the dimensions of a room, providing for all the nuances.

Measuring the kitchen, as well as other rooms, is best left to professionals who know what to look for and what can be overlooked as insignificant.

Usually, experienced measurers come to the address “fully armed”. That is, in addition to many years of experience behind them, they have a professional tape measure (most often laser), a level, a square, a plumb line and a standard template for measurements.

Types of forms for measurements:

Form sketched "by hand" with the customer

Such a template is a sign of a not quite competent master, accustomed to doing everything in haste.

Without paying due attention and in a hurry during the initial measurement of the room, he shows the level of his skill: about the same, carelessly, the furniture maker will develop the project, and then make the kitchen set.

Such forms are successfully used by both garage furniture makers and small entrepreneurs who have been able to save up for a printer, but do not yet have the proper level to use special furniture programs.

Form on which the initial sketch of the kitchen has already been drawn

A measurer with such a template simply substitutes the dimensions of kitchen cabinets, without going into too much detail about communications.

Similar drawings can also be found in furniture stores that sell ready-made (standard) kitchen furniture.

Form indicating the main communications and facilities

Large furniture companies have several printed templates for the standard layout of apartments and a blank form for atypical, individual layouts.

In addition, measurers from large companies always have a camera with them for detailed fixation of complex knots.

Measurements made in accordance with all the rules of furniture production are the guarantor of prompt installation of the kitchen.

Due to the individual dimensions and location of important objects, during installation there is no need to cut furniture parts, return the set to production for rework, or lament over unaesthetic appearance kitchens.

Always yours, Timur Denisov

Correctly measuring the kitchen without a minimum experience in such matters is not so simple, but sometimes it is simply necessary. You have to make independent measurements when you plan to purchase a kitchen set yourself and assemble it yourself too, if the manufacturer-seller cannot provide such a service, or if you purchase already assembled kitchen furniture. Also, a high-quality independent measurement of your kitchen can save you from unnecessary visits to shops-offices of manufacturers and sellers of kitchen furniture.

Self-measurement of the kitchen should be carried out with the utmost care. Remember that a lot depends on your accuracy, and you will have no one to blame for errors in your measurements.

To measure the kitchen space, you will need the most common construction tape of sufficient length. Do not use "decorative" short "meter" roulettes, with them any measurement of the kitchen will become torture for you and is fraught with possible mistakes. Professional measurers use a laser tool that allows them to take measurements alone. For you, if you have an assistant, for a completely acceptable quality of measurements, a simple, non-laser tape measure will be enough.

When taking measurements, keep in mind the "infinite errors of builders" that the length of the wall at the bottom is not always equal to its length at the top. Measure for each piece of furniture exactly in the same place and exactly at the same height where this furniture will be located. Record all measurement results immediately, do not rely on your memory. It is very convenient to use pre-prepared kitchen measuring sheet.

Responsible kitchen furniture manufacturers that take orders remotely will not even accept your order if you do not provide a detailed and high-quality measurement of your kitchen space. Many of them send their potential customers a kitchen measurement form of their own sample, in which the client will need to put down the results of their own measurements (to the nearest millimeter). Such forms should contain detailed information about all possible objects in the kitchen that require measurements and fixation on the plan of the kitchen. Such objects are most often pipes for heating, sewerage, water supply and gas supply, windows-doors, ventilation, the location of electrical outlets, and so on. Manufacturers, as a rule, have several such forms, because they try to prepare standard measurement forms for most typical kitchen premises, thereby simplifying the work of producing independent measurements for their potential customers.

Below is a sample of such a form for your reference. For your own needs, you can copy the presented one, or then make your own based on it, so that measuring the kitchen becomes more comfortable and as accurate as possible for you.

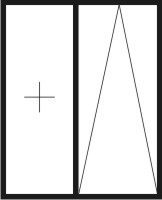

Before you go to order a window, you need to transfer the results of your measurements to paper, i.e. draw up a sketch of the product, and this must be done in the form in which it will be clear to the manager of any window company, no matter which one you apply to. In order for your drawing to look professional, no worse than that of a real measurer, and as a result you have purchased a product of exactly the configuration that was intended (for example, the deaf and opening sash were not mixed up in places, the dimensions were exactly observed, etc.), you need to know some rules for the design of a measuring sheet.

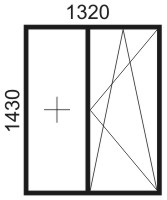

Firstly, on all documents (measuring sheet, contract), a drawing of a plastic window is made as a view. This is very important so as not to confuse the location of the sash and the blind part of the window relative to each other.

Secondly, all dimensions are in millimeters.

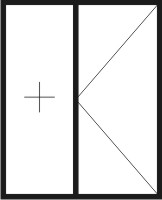

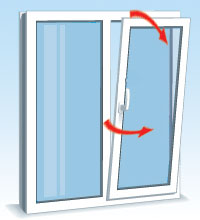

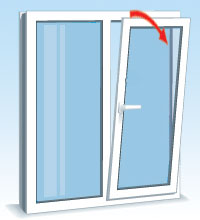

Thirdly, it is necessary to schematically depict the presence of a blind part (if any) and a sash (if any), as well as the type of its opening. The three most common types of sash opening are: rotary, swing-out, fanlight(folding). The following table shows, as an example, how a window with right sash in the three indicated options:

Icon " + " in the left half shows that there is a double-glazed window in the blind part of the window. In special occasions instead of a double-glazed window, an opaque element can be installed - a sandwich panel. In this case, instead of the " + "write" sandwich "or abbreviated" sand ".

It is easy to guess that with the help of a triangle it is indicated on which side the hinged side of the sash (hinge) is located.

Also, the angle of the triangle opposite the hinged side shows where the opening comes from. In the previous example, the sash opens from left to right.

If necessary, the loop side can be transferred to the impost. In this case, the sash will still be considered right, but its hinge will become left, i.e. it will open from right to left. Schematically it will look like this:

Now you can come up with any configuration for your window and draw it in the form of a diagram. Here are some examples:

I must warn you that there are restrictions on the maximum and minimum dimensions sashes, therefore, alas, not any of your fantasies in terms of window configuration can be translated into reality. More specific information on this subject will be given to you at the office of the company, where you will contact when ordering a window.

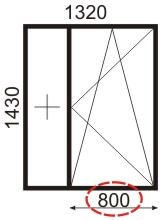

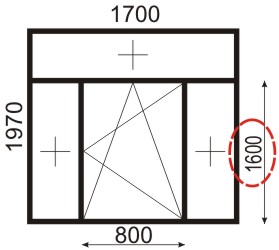

Of course, the bare scheme of the window alone will not be enough to manufacture the product. Your drawing should be supplemented with specific figures: window height, window width, sash size, as well as an indication of the type of profile, type of sealant (rubber band), type of fittings, thickness and other parameters of the double-glazed window. The dimensions of the window, as already mentioned, must be indicated in millimeters. It looks something like this:

The width of the sash can be chosen as you like, but you should not forget that too wide sashes are more prone to sagging due to their heavy weight. There are two common options:

1 - "in geometry "when the vertical impost divides the window into equal parts, while the double-glazed window of the sash turns out to be less wide than the double-glazed window of the capercaillie, but with this configuration, the cost of the window decreases;

2 - "by lumen ", when the impost is slightly shifted from the center towards the capercaillie, but due to this, equality of the width of the double-glazed windows of the capercaillie and the sash is achieved.

You can indicate in writing any of these options in the measurement sheet, or indicate the specific width of the sash in numbers on the diagram if the previous two options do not suit you:

In the case of a more complex window design, it will be necessary to additionally specify the height of the sash, as in the following example:

By the way, if you do not specifically note that you indicated the height of the sash, then in the computer program that calculates your product, the size " 1600 " (from the previous example) will be taken as the distance from the bottom edge of the frame to the centerline of the horizontal mullion.

It is better to discuss the remaining parameters of your window directly with the company manager when you place an order, because the types of PVC profiles and possible options in the design of windows for each company may be different. And before you go to order a window, I recommend reading,